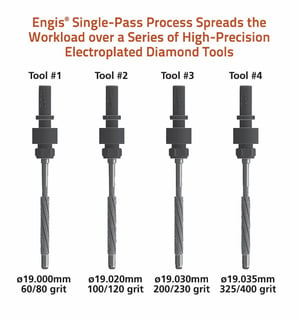

The Single-pass honing/bore finishing process involves a series of pre-set diamond coated tools that get passed through a bore with a single in-and-out stroke movement while the tool, part, or both are rotating.

Product Focus:

Single-Pass Bore Finishing vs. Conventional Honing

Conventional hole finishing/bore honing utilizes a tool with cutting surfaces that expand and contract as the tool reciprocates in the bore through the cycle. Unfortunately, simultaneous radial and axial movement makes controlling bore size (ID) and geometry (cylindricity) more difficult. Conversely, the Engis single-pass bore finishing process uses fixed-size bore finishing tools electroplated with diamond abrasive particles. These tools pass through the bore only once, removing a specific amount of material. Using a series of progressively larger bore finishing tools (coated with progressively finer superabrasive particles) enables precise and repeatable control.

Shortest Cycle Times in the Industry

Superior Quality with Engis Single-Pass